![]()

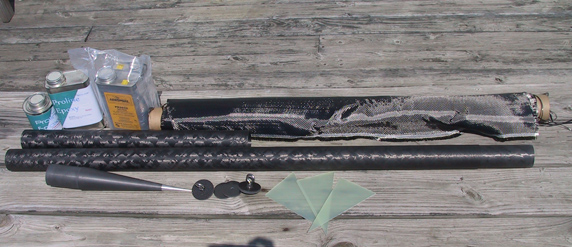

Construction finally started on the Mach Factor 2 project. With JP getting his own place and moving out and Ben’s High School Graduation with senior week in Ocean City, there were just not any weekends to start construction until mid June. We got together and started the most difficult and time consuming aspect of this rocket, the fins.

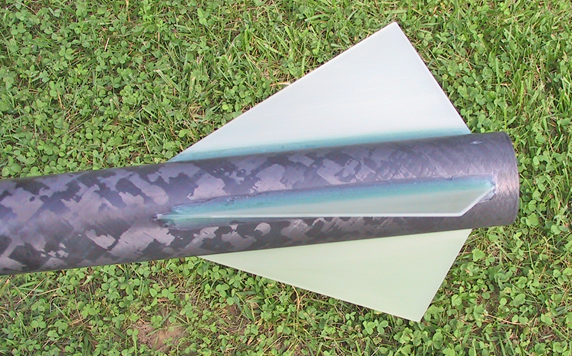

The 54mm airframe will act as the main engine tube so "through the wall" fin mounts were not an option. The fins have to attach to the outside of the airframe in a manner to withstand mach 2 speeds. The fins also have to be attached straight and in perfect alignment. Too much variation could cause the rocket to shutter or spin and at mach speeds the rocket would tear itself apart and disintegrate. We chose to use three G10 1/16 inch fiberglass fins that would form the core after 2 layers of carbon fiber wrapped lamination to the main airframe. This setup should hold the fins together if acceptable alignment can be achieved.

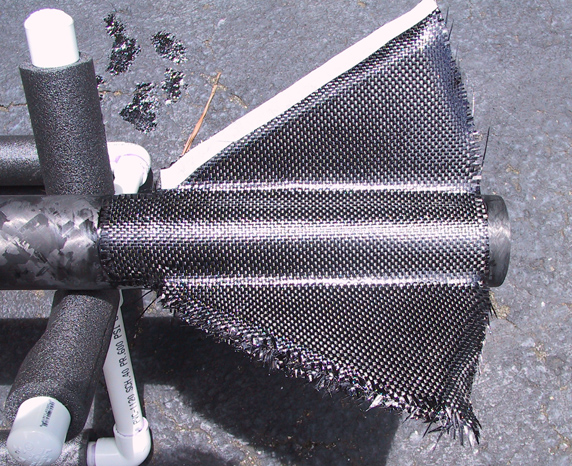

A fin alignment pattern was downloaded, printed, and attached to a piece of stiff cardboard. The position of the Slimline Motor Retention System was marked on the main airframe as well as the position of the three fins. An old Estes fin alignment tool was dusted off and used to hold the fins in position. 5-minute epoxy was used to tack the fins in place. After many hours of aligning, eyeballing, measuring, breaking off and starting over, re-measuring, re-tacking, yelling colorful metaphors, we finally had the fins tacked in place and in what we believe is perfect alignment. Fin fillets were quickly added to reinforce the fiberglass G10 fin cores until they can be wrapped in carbon fiber. Sanding of the fin fillets, fins, and lamination area was completed with 80-grit sand paper.

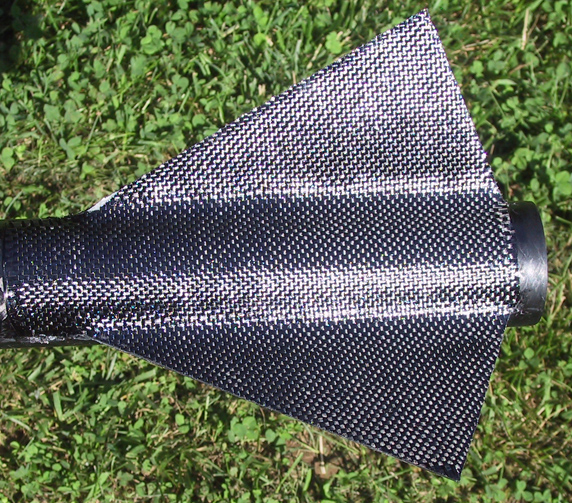

Old newspaper was used to create a template for the carbon fiber fin wraps. Two layers of carbon fiber were cut and Aeropoxy was used to laminate the two carbon fiber layers fin tip, over the airframe, to fin tip. Time was taken to ensure no air bubbles remain within the lamination. After curing for 6 hours, a sharp razor was used to trim the excess. The wrap was allowed to fully cure for 24 hours before repeating two more times for the remaining fins. The fins were sanded with 120-grit sandpaper and another coat of Aeropoxy was applied with a foam brush to finish filling the weave.

The fin can was sanded and faired again. JB Weld was mixed and the Slimline engine retention system was permanently bonded to the aft end. The sanding and fairing continued until the aft fin area appeared to have been molded from one piece. The fin section was now completed.

As fast as June started, it was over. July will hopefully bring the completion of the electronics bay and the installation of the all so important flight computer. A name for the rocket still has to be agreed upon as well and has been narrowed down to two possibilities. To be continued in July . . .