![]()

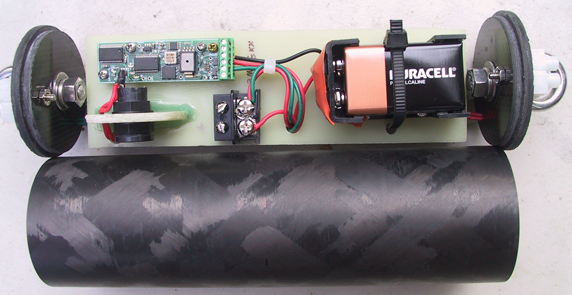

Ground testing was next. Drawing on my ejection experience from Shaken, Not Stirred, I calculated that 1.5 grams of black powder should be sufficient for both apogee and main ejection charges. The Rocket was prepared as if ready to fly. All shockcords, heat shields, and parachutes were packed and the rocket taken outside. An old comforter was used to slightly elevate the ejection.

As in real flight, the apogee ejection was tested first. The apogee ejection occurred successfully but seemed kind of wimpy. Closer inspection revealed that the bulk of the ejection energy pushed the forward enclosure of the empty motor casing aft. This would not occur if an engine was loaded into the case. During actual flight, the apogee ejection would be a little more violent. However, in rocketry circles the saying goes, blow it apart or blow it up. I will put 1.75 grams into the checklist.

Next was the main ejection test. There were two shear pins holding the nose cone. Again the calculations showed that 1.5 grams should do the trick. Toni performed a 5-second countdown while I took video. The two shear pins popped and the nose cone shot off taking the main recovery gear with it. See the main ejection test here.

The empty engine case was removed and the rocket was weighed for its final weight. It weighed 4 pounds and 4 ounces. The Center of Gravity was also verified and it was 41.5 inches aft of the nose cone tip. The entire rocket was cleaned and given a final light sanding with 400-grit sand paper. Krylon Pumpkin Orange was chosen as the color. Three coats of Pumpkin Orange were applied to the bottom and top portions of the rocket.