The pieces of the Mars Lander stood in the box,

collecting dust until July, when time finally presented itself. I took

the box of parts off the shelf and re-read the instructions, and then

again, and then again. I opened the epoxy only when I finally felt

confident that I knew where all the parts go. I decided to stick to

the instructions since I never built a Mars Lander before. I also found

Jeff

Brundt's build of his Mars Lander and

the pictures on the

Mars

Lander website helpful. I also often glanced at

Richard

Pitzeruse’s Mars Lander as inspiration to complete this project. I

figure I would pound each construction step out until eventually there

were no more construction steps remaining.

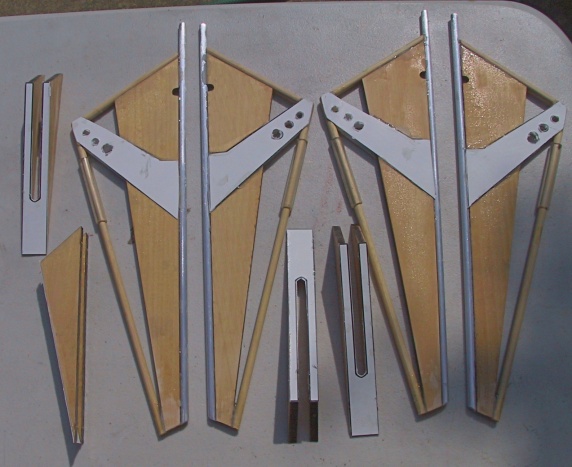

I took the gear housings and legs and sealed them with a light coat of

West System. I then carefully cut the gear housing covers from the

cardboard stock that was included with the kit. I check, and recheck

multiple times as to the orientation of the gear housings and the gear

housings covers. I applied epoxy once I was satisfied. I then set the

gear housing assemblies aside and started my efforts on the legs.

The Mars Lander legs are not for the faint hearted. There are many

pieces and I found myself referring to the instructions and the various

web sites many times until I had a clear understanding of their

construction.

Using the provided templates, I cut the four long dowels into the long

strut braces and cut an additional dowel into four short strut braces.

The four long aluminum strut braces were already cut. I scratched the

aluminum with some sand paper and epoxied the aluminum leg braces to

the bottom of each leg. I also epoxied the short dowel to the upper

part of the leg. Once dried, I cut the provided clear tubing using the

template and slid it onto the remaining four dowels at the location

indicated in the template.

I cut the eight gear strut supports from the cardboard stock. I used a

drill to cut the holes but that idea did not work as well as I had

hoped. The drill tended to shred the cardboard on the edges. I glued

one gear strut support to each of the four legs. I then epoxied the

long dowel strut and then the other gear strut support to the leg. The

landing pads were next.

I happen to have part of a 38mm motor tube and cut four ¼

sections off of this tube using a miter box saw. These became the pad

rings. Each landing pad consisted of a bottom pad, lower disc, pad

ring, upper disc, and two supports. The pads were assembled and then

epoxied to each leg with the supports. Each lander leg was then tidied

up using sandpaper and body filler. Care must be given to the cardboard

gear strut support when sanding. The legs were then primed and hung out

to dry.

July comes to an end and I have, for the most part, completed steps 1 –

12. Only 35 more steps to go.

![]()